- All copper concept

- ALL COPPER Spirit

- All copper process

copper

At the beginning of its establishment, Jiajia Lighting insisted on using H65 precision cast brass as lamps;

Iron lamps are easy to rust, zinc alloys are easy to oxidize, and copper does not rust.

copper function

Copper is the only metal certified by the U.S. Environmental Protection Agency (EPA) to kill harmful bacteria;

Feng Shui has been made into a mascot for town house and evil spirits.

The history of copper

It was first used between 1700 and 1000 BC,Various handicrafts are made of copper for use by royal relatives and nobles. Bronze can be used for thousands of years. Homelist hopes this all-copper lamp will accompany you through your golden wedding.

THE MEANING OF COPPER

It is made of pure brass, with its own temperature and advanced sense, and is full of noble metallic yellow,

It will slowly oxidize (but will not be corroded) with the passage of time,

showing a more simple and restrained unique luster.

COPPER ART INHERITED

Inheritance of copper art

The all copper spirit advocated by HOMELIST lighting ,

is better with the precipitation of years through the simple

and restrained luster of all copper and the continuous gorgeous, unrestrained and tenacious vitality.

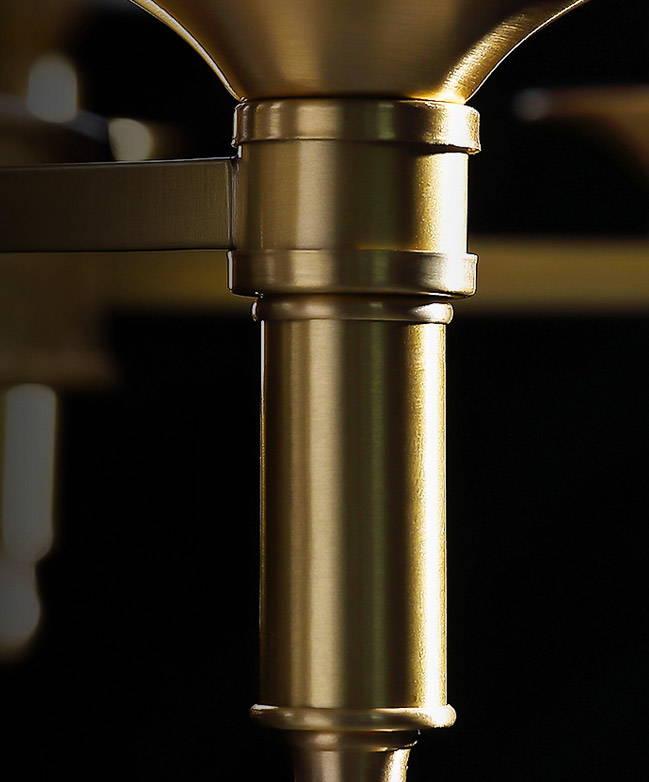

All copper lamps form

A piece of brass needs 72 processes to become a high-quality and qualified copper lamp.

A journey of 72 procedures, from materials to techniques, at the beginning of each cultivation path, a senior and rigorous master is waiting for it. Must be GB H65 brass. It has good mechanical properties, strength and plasticity, as if carefully designed to become a copper lamp. In the subsequent repeated hot and cold pressing, cutting and welding, it can survive and perform flawlessly and withstand the erosion of the years.

Acid removal, rust prevention, triple sealing glaze, high temperature baking paint. The triple baptism makes it "invincible": water molecules in the air cannot corrode it, oxygen in the air cannot oxidize it, and the word "lasting freshness" seems to be tailor-made for it.

ancient way

Sand casting is a process of producing castings with clay-bonded sand as the molding material. It is about 5000 years old. China entered the heyday of bronze castings from 1700 BC to 1000 BC.

high-strength stamping

Homelist uses imported high-strength mechanical punching machines for stamping, which can process workpieces such as stiffeners, ribs, corrugations or flanging that are difficult to manufacture by other methods, making the metal flow line more smooth and complete.

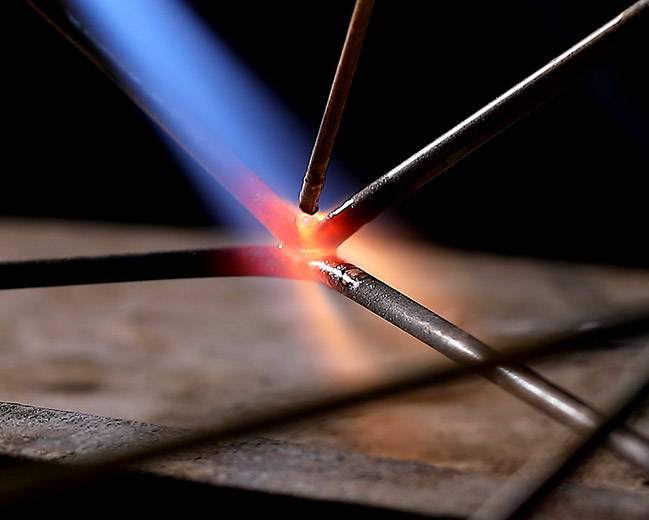

welding

700℃ high temperature welding, using excellent

Silver electrodes with a silver content of 20%,

Has excellent process performance: strong fluidity,

Good wettability and ability to fill voids,

It is convenient to remove

Weld marks left by the brazed area.

In this way, it can be said that HOMELIST

The chandelier is finely crafted.

level control

Leveling is the quality control of copper lamp parts,

This is not only related to the beauty of the copper lamp, but also affects the smooth assembly and durability of the copper lamp.

Homelist deploys experienced craftsmen in this important link to precisely control and ensure quality.

fine polishing

Homelist Brass Hand Polished

on special polishing machines, and grinding

Eliminate marks by grinding and rolling

very fine polishing powder and

Grinding surface; complete process

After a total of 6 rough polishing and

Fine polished. Polished using soft wool fabrics and

Ultra-fine polishing powder, showing fineness

and soft copper texture.

coloring process

In order to solve the problem of copper oxidation,

homelist product experienced more than 6 times

Coloring processes such as cleaning, degreasing,

Water foams, stains, finishes and rubs,

Gives the composition of copper a variety of colors

and surface color to meet product requirements

decoration and design.

140℃ high temperature baking paint

After the copper parts enter the oil chamber, the imported high-grade varnish is used to seal the oil to ensure that

Copper parts are not easy to oxidize and turn black in the natural state.

The natural color of copper needs to be baked at a high temperature of 140 degrees for 30 minutes.

Turn off the furnace after 20 minutes of constant temperature; copper black needs to be baked at 80 ℃ for 40 minutes,

And turn off the oven thermostat for 20 minutes.